Chemical Engineering Process Flow Diagram Software Free Download

Feel free to try this handy P&ID diagram design maker. Things you can do:. Finish projects on Windows, Mac or Linux OS. Drag and drop lots of built-in symbols and marks on the unlimited drawing canvas. Have a quick start based on the rich tem. A huge collection of online process engineering tools provided by Process Associates of America. Prode Calculator Tool for solving problems in chemical engineering on the PC. Free preview version can be downloaded. Software Tools for Process Integration An independent list of process simulation tools from Aspen Plus to Supertarget.

Contents

What is a Process Flow Diagram (PFD)?

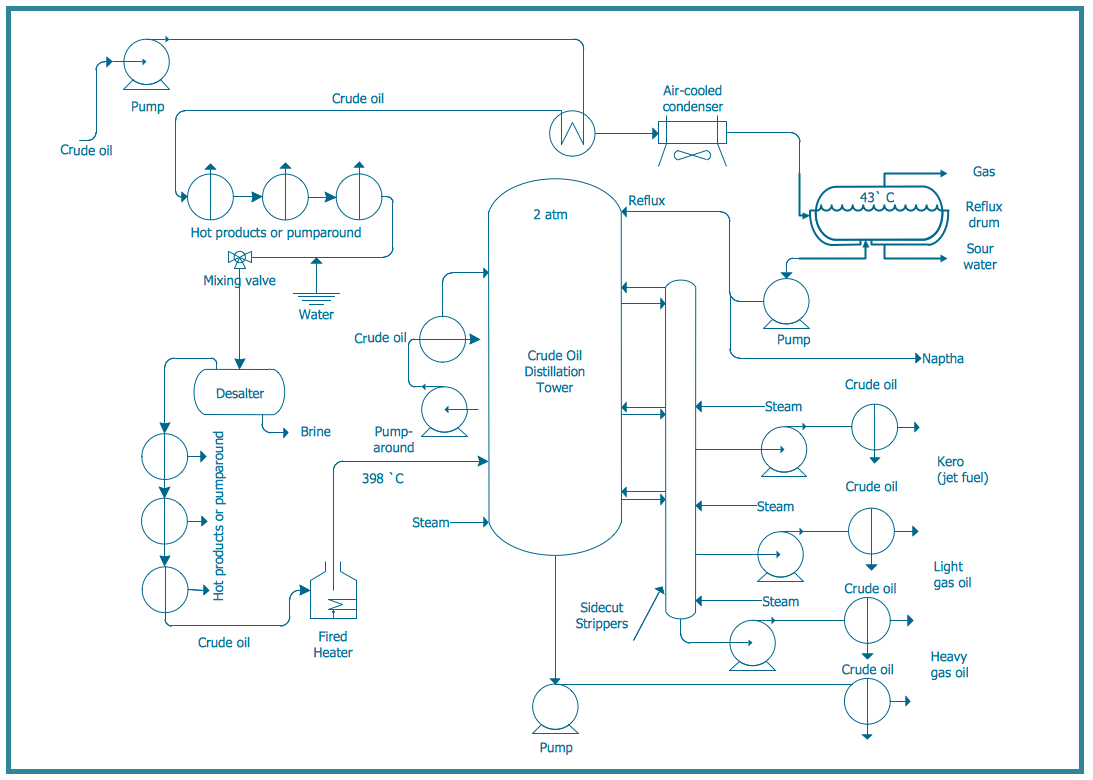

Process Flow Diagram (PFD) is a commonly used chart in chemical engineering and process engineering demonstrating the ongoing production flow of chemicals and other types of equipment involved.

The concept of the process flow diagram was first pointed out by Frank Gilbreth, an American industrial engineer, in the 1920s. In the following decades, process flow diagram has become popular in various forms in the industrial engineering industry and even in the business sector.

Why Use the Process Flow Diagram?

Generally, a process flow diagram is an indispensable tool in modern engineering application since it can be used in various stages of process engineering: from planning to information management, from capacity management to resource organization, and from decision analysis to cost calculation, etc. Process flow diagrams can also help:

- Clearly observe and monitor the entire production process, such as how many components are included, what are the raw materials etc.

- Re-examine problems, obstacles, the causes of delays and uncertainties during a production process.

- Department managers to deal with information management and documentation, capacity planning of chemical materials, technological development of mechanical equipment and so on.

- Building a new model to improve production efficiency.

- Enhance communication and collaboration among various roles within and outside the organization.

Process Flow Diagram Symbols

You can use either black-and-white or colored process flow diagram symbols as shown below to easily show the functional relationships between system facilities and devices. It is also convenient to transport flluid substances in your diagram by inserting pipes.

What are the Relationships between Process Flow Diagrams and P&IDs?

Another type of graph that has been mentioned many times with process flow diagrams are piping and instrumentation diagrams (P&ID). These two share some common points but they also have considerable differences:

- Both process flow diagrams and P&IDs contain a series of standard symbols for users to describe a process.

- P&IDs normally include more details than process flow diagrams, since the latter type mainly show the relationship between main equipments. Usually, a process flow diagram includes process pipelines, major equipment items and control valves, etc. However, process flow diagrams generally do not include pipeline grades, pipeline numbers, or secondary bypass lines, etc.

- In practice, process flow diagrams can be used for new employee training, while P&IDs is generally used by process technicians such as pipeline designers, electrical engineers, instrumentation engineers and other technical experts for their production development.

Related Forms of the Process Flow Diagram

Block flow charts (BFD)

BFDs can also be used to simplify and decompose process flow systems. Moreover, such diagrams are the simplest form of the industrial flow chart and are usually considered as the first step to complete a process flow diagram. Blocks in BFDs can represent anything from a single device to the entire plant, and links between blocks represent process flows (liquids, solids, gases etc.). BFD is easy to understand, therefore it can be read by users with limited experience in flow charts, or by non-professional industrial operators (e.g. business managers and government agencies officers).

Schematic diagram

This type of diagram mainly shows a system with understandable graphical symbols instead of real pictures. Such diagrams also omit details that are not relevant to the diagram to minimize visual confusion. In a schematic diagram of the chemical production process, symbols are generally used to represent the equipment of the system and their interconnection paths.

More Free Process Flow Diagram Templates and Examples

Here are more templates of process flow diagrams for you to easily undertake your projects. All of these are editable with the free download process flow diagram software. Feel free to click on any of them to see more details.

| Sulfric Acid PFD Template | Mortar Production PFD Template | Chemistry PFD Template |

| Beer Production PFD Template | Demineralized Water PFD Template | Drying Equipment PFD Template |

How to Plan and Draw Your Process Flow Diagram?

First of all, we need to download a process flow diagram maker - Edraw Max

Edraw Max: a swiss knife for all your diagramming need

- Effortlessly create over 280 types of diagrams.

- Provide various templates & symbols to match your needs.

- Drag and drop interface and easy to use

- Customize every detail by using smart and dynamic toolkits.

- Compatible with a variety of file formats, such as MS Office, Visio, PDF, etc.

- Feel free to export, print and share your diagrams.

In general, you need to follow the following steps to plan and produce a process flow diagram:

Step 1: Set Goals

Identify your research objectives and specific details. In this case, you may need to share updated ideas within your department or with external partners.

Step 2: Do Researches

Research your equipment through detailed observations and interviews. Also integrate any available data sets if you need to model a new process.

Step 3: Summarize and Outline

Summarize all the information you have gained so far and outline the process steps. You can use a note to complete your draft on a large piece of paper.

Step 4: Create Your Process Flow Diagram

Use an intuitive professional process flow diagram software to draw more details about your project. Make sure that your entire team is involved in discussing any important changes. Bww rocky music download. You can do the following to build your diagram:

Step 4.1: Drag and Drop Shapes

Drag and drop built-in standard process flow diagram symbols in the library. Alternatively, you can use a preset template to faster your work.

Step 4.2: Connect Elements

Connect process flow diagram shapes and equipment with pipelines in different directions. Adjust the length and width of a pipeline according to your specific needs.

Step 4.3: Edit Elements

Customize your process flow diagram shapes by changing the default color and size. You can further add text to or label each of the equipment.

Step 5: Save and Share

Once done your process flow diagram, remember to save it on built-in personal or team cloud to share with other departments for different purposes (such as quality document management, new employee training, etc.). You can also export your files to different formats including PDF, SVG, Visio, Graphics etc.

How to Create a Process Flow Diagram with Edraw Max?

Use the multi-platform based Edraw Max to create your own professional-looking process flow diagrams. Feel free to enjoy the intuitive drag-and-drop user interface and explore the rich preset categorized symbols. You can also auto-connect, label, or font your shapes quickly by using the built-in auto-create tools. Once finished your work, easily export to many different formats including PDF, SVG and Visio, or save on the Edraw personal or team cloud to collaborate with your colleagues. If you previously used Visio for your work, simply import it into Edraw Max for further improvements. See how easy it can be by clicking on the free download button at the end of this page right now!

Explore More:

- Free Download Software Conceptdraw For Pfd And Pid

- Chemical Process Flow Diagram Software Free Download

- Chemical Engineering Software Free Download

- Chemical and Process Engineering Template Plant Pid

- Valve Symbols For Pid

- ConceptDraw Software Full Versions Free Download Free Drawing ..

- Piping Design Software Free Download

- Software Engineering Projects Examples Free Download

- How to Draw a Process Flow Diagram in ConceptDraw PRO ..

- ConceptDraw Arrows10 Technology Design elements - Chemical ..

- ERD Entity Relationship Diagrams, ERD Software for Mac and Win

- Flowchart Basic Flowchart Symbols and Meaning

- Flowchart Flowchart Design - Symbols, Shapes, Stencils and Icons

- Flowchart Flow Chart Symbols

- Electrical Electrical Drawing - Wiring and Circuits Schematics

- Flowchart Common Flowchart Symbols

- Flowchart Common Flowchart Symbols

- Flowchart WBS: Advantages And Disadvantages Of Work Breakdown Structure

- Flowcharting Methodology IN RUP: Advantages And Disadvantages Of Rational Unified Process in Software Development Project Management

- Project Management Department IN PMO: Matrix of Roles and Responcibilities in Programmes and Projects. Application Support Manager Duties.